Underrated Ideas Of Info About Is A VFD Motor Controller

Is a VFD a Motor Controller? Unraveling the Mystery

1. What's the Deal with Motor Control Anyway?

So, you're diving into the world of motors, huh? Fantastic! You've probably heard whispers of "motor controllers" and maybe even stumbled upon the enigmatic "VFD." The big question is: Is a VFD (Variable Frequency Drive) really a motor controller? Let's put on our detective hats and explore this electrifying topic.

Think of motor control like the reins on a horse-drawn carriage (if those still exist!). You need a way to tell the horse (the motor) to go faster, slower, or even stop. A motor controller, in its broadest sense, is anything that manages the operation of an electric motor. That includes starting, stopping, speed control, torque control, and protection. It's the brains behind the brawn, making sure your motor doesn't run amok.

Now, there are many different types of motor controllers. Some are simple, like a basic on/off switch. Others are more sophisticated, offering precise control over various motor parameters. Understanding this variety is key to understanding where VFDs fit into the picture. Consider it like ordering coffee — you have your basic black coffee, your latte, your cappuccino, and then... something really fancy with foam art. All coffee, but different levels of complexity, right?

In essence, motor control ensures optimal motor performance, prevents damage, and contributes to overall system efficiency. This is crucial in many industrial and commercial applications where precise motor operation is paramount. Without proper control, motors can overheat, experience excessive wear and tear, or simply fail to deliver the required performance. Think of a washing machine motor without a controller it would just spin at full speed constantly, making a mess!

What Is A Variable Frequency Drive (VFD)?

VFDs

2. Diving Deep into Variable Frequency Drives

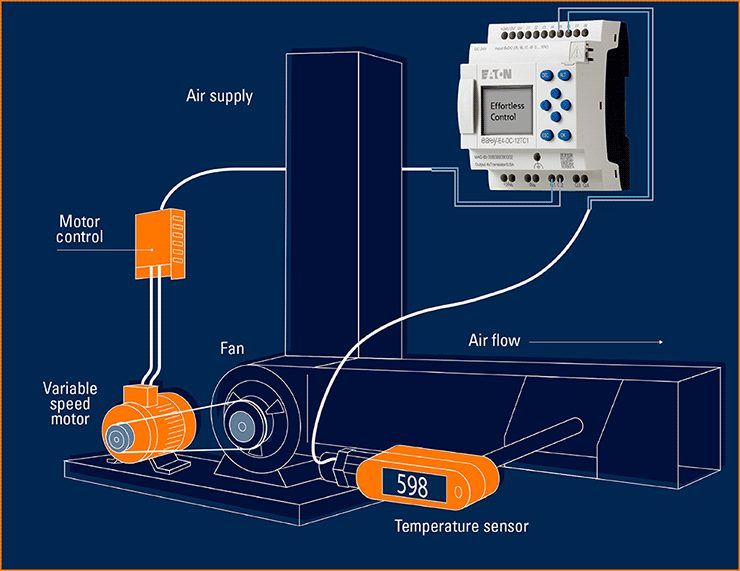

Okay, let's zoom in on the star of our show: the VFD. A VFD is a specific type of motor controller. It stands for Variable Frequency Drive, and the name pretty much gives away its superpower: it controls the speed of an AC (alternating current) motor by varying the frequency of the electrical power supplied to it. Think of it as a volume knob for your motor's speed.

How does it work its magic? Well, a VFD takes the incoming AC power, converts it to DC (direct current), and then converts it back to AC at the desired frequency. This clever manipulation allows the VFD to precisely control the motor's rotational speed. Its like having a master conductor controlling the orchestra of electrical signals.

The benefits of using a VFD are numerous. First and foremost, it provides precise speed control, allowing you to optimize motor performance for different tasks. This is a big deal in applications where consistent speed is crucial, like conveyor belts or pumps. Second, VFDs can significantly reduce energy consumption. By running motors at their optimal speed, they avoid wasting energy on unnecessary acceleration or deceleration. This efficiency translates directly into cost savings.

Beyond energy savings and precise control, VFDs also offer advanced protection features for your motor. They can monitor various parameters, such as voltage, current, and temperature, and automatically shut down the motor in case of a fault. This protection helps to prolong the lifespan of the motor and prevent costly repairs. Its like having a vigilant guardian watching over your precious mechanical asset.

VEVOR VFD Drive Inverter 220V 3KW 4HP 13A Frequency

So, is a VFD a Motor Controller? The Verdict!

3. Putting it all Together

The answer, my friends, is a resounding YES! A VFD is a motor controller, but it's a specific and quite advanced type of motor controller. It's like saying a sports car is a car — technically correct, but it doesn't tell the whole story. VFDs offer a level of control and efficiency that simpler motor controllers simply can't match.

Consider this analogy: a dimmer switch is a type of light switch, but it offers more control than a simple on/off switch. Similarly, a VFD is a type of motor controller, but it provides far greater flexibility and functionality compared to basic starters or contactors. It's the Cadillac of motor controllers, offering a smooth ride and plenty of bells and whistles.

Choosing the right motor controller depends heavily on the specific application. For simple applications where basic on/off control is sufficient, a VFD might be overkill. But for applications requiring precise speed control, energy efficiency, and advanced protection, a VFD is often the best choice. It's all about matching the right tool to the job.

Ultimately, understanding the relationship between VFDs and motor controllers empowers you to make informed decisions about your motor control systems. Whether you're an engineer, a technician, or simply a curious learner, this knowledge will help you optimize motor performance, reduce energy consumption, and ensure the longevity of your equipment. So, embrace the power of control and let your motors run smoothly!

When to Use a VFD vs. Other Motor Controllers

4. Making the Right Choice

Okay, we've established that a VFD is a fancy-pants motor controller. But when do you actually need one? It's not always the best choice, especially if you're just trying to make a fan spin in your garage (though you could!). Let's break down the scenarios where a VFD shines and where other, simpler motor controllers might be more appropriate.

Think about applications where variable speed is crucial. Pumps are a great example. Imagine a water pump in a building. Without a VFD, it would run at full speed constantly, even when demand is low. A VFD allows the pump to adjust its speed based on the actual water demand, saving energy and reducing wear and tear. Similarly, in HVAC systems, VFDs can control fan speeds to maintain optimal temperature and airflow.

On the other hand, if you're dealing with a simple application where constant speed is sufficient, a basic motor starter might be all you need. For instance, a conveyor belt that always needs to run at the same speed doesn't necessarily require a VFD. A simple on/off switch and a motor starter can get the job done just fine. It's like using a regular screwdriver instead of a fancy power drill for a simple task.

Cost is also a significant factor. VFDs are generally more expensive than other motor controllers, so if budget is a major constraint, a simpler option might be more appealing. However, it's important to consider the long-term cost savings associated with VFDs, such as reduced energy consumption and extended motor lifespan. Sometimes, the initial investment in a VFD can pay for itself over time.

Troubleshooting Common VFD Issues

5. Keeping Things Running Smoothly

Even the best technology can sometimes throw a curveball. VFDs, for all their sophistication, are not immune to occasional hiccups. Knowing how to troubleshoot common VFD issues can save you time, money, and a whole lot of frustration. Let's look at some typical problems and how to address them.

One common issue is nuisance tripping. This occurs when the VFD unexpectedly shuts down, often due to a fault condition. Check the VFD's display for error codes, which can provide valuable clues about the cause of the trip. Common causes include overcurrent, overvoltage, undervoltage, and overheating. Ensure that the motor is properly sized for the application and that the VFD's parameters are correctly configured.

Another common problem is motor overheating. This can be caused by excessive load, incorrect VFD settings, or insufficient cooling. Check the motor's temperature and ensure that it's within the manufacturer's specifications. Verify that the VFD's output frequency is appropriate for the motor's speed and that the cooling fan is functioning properly. If the motor is overloaded, consider reducing the load or using a larger motor.

Communication problems between the VFD and other devices can also occur. Check the communication cables and connectors to ensure that they are properly connected and free from damage. Verify that the communication parameters, such as baud rate and parity, are correctly configured on both the VFD and the other devices. If necessary, consult the VFD's documentation for troubleshooting guidance.

FAQ

6. Q

A: Not every AC motor, but most modern induction motors are compatible. Older motors might not be designed to handle the variable voltage and frequency that a VFD outputs. Always check the motor's specifications and consult with a motor specialist if you're unsure. It's like trying to put modern tires on a Model T — it might not work so well!

7. Q

A: Potentially, yes! If you're running a motor that doesn't always need to be at full speed, a VFD can significantly reduce energy consumption by adjusting the motor's speed to match the actual demand. Think of it as only using the amount of water you need instead of letting the tap run full blast all the time.

8. Q

A: Installation can range from relatively straightforward to complex, depending on your experience and the complexity of the system. It's generally recommended to have a qualified electrician or technician handle the installation to ensure it's done safely and correctly. Messing with electricity is never a good idea unless you know what you're doing!