Matchless Tips About Do DC Motors Need Controllers

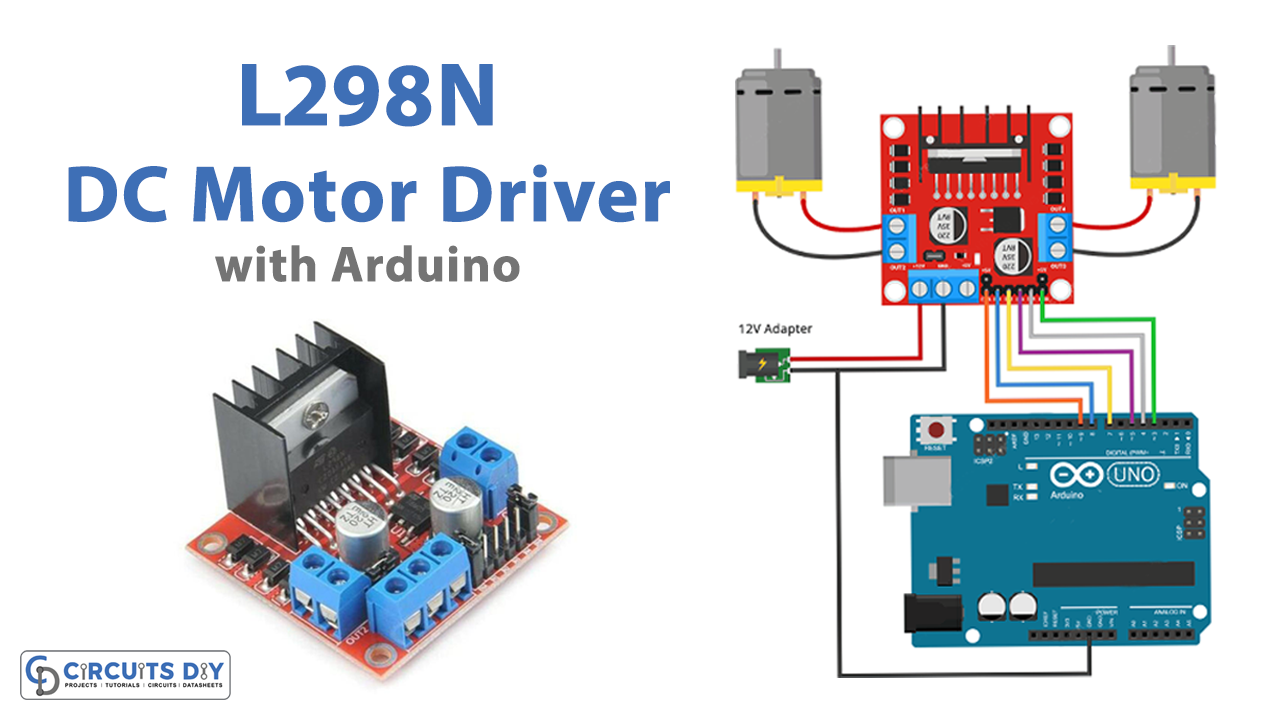

Controlling DC Motors With Arduino And L298n Motor Driver, 43 OFF

Do DC Motors Need Controllers? Let's Get This Straight

1. Why We're Even Asking This Question

So, you're tinkering with a project that involves a DC motor, or maybe you're just curious about how things spin. Either way, you've stumbled upon a great question: "Do DC motors need controllers?" It's like asking if your car needs a steering wheel. Can it technically move without one? Probably. Will you end up in a ditch? Almost certainly! Lets unravel this mystery, shall we? Think of controllers as the conductors of a DC motor's orchestra, ensuring a harmonious performance instead of a chaotic noise.

Many electronics enthusiasts jump right into hooking up a battery to a DC motor and watching it whir. While that works (sort of), it's like playing a guitar with just one string and no tuning. You're missing out on a whole symphony of possibilities. We need to dive into the nuances, the subtle control that can make a DC motor truly sing (or, you know, efficiently perform its task without burning out).

Imagine a simple toy car. It probably has a DC motor, and when you flip the switch, it zooms forward at one speed until it crashes into something. That's an uncontrolled DC motor in action. Functional, yes, but far from elegant or precise. Real-world applications often demand a more sophisticated approach, something that allows for variable speed, direction control, and protection against overloads.

Before we get too deep, lets put the suspense to bed. The short answer: No, DC motors don't absolutely need controllers to function, especially the simplest ones. But if you want anything beyond basic on/off functionality — like, say, control over its speed, direction, torque, or even its lifespan — then a controller isn't just a nice-to-have; it's essential. Think of it as graduating from crayons to a digital art tablet. Both can create art, but one offers far more possibilities.

Brushless DC Motors With Controllers, Gearboxes, Worm

Understanding the Role of DC Motor Controllers

2. What Exactly Do These Controllers Do?

DC motor controllers are the brains behind the brawn. They manage the power going to the motor, allowing you to manipulate its behavior in various ways. A basic controller might simply regulate the voltage to control speed. A more advanced controller might incorporate feedback loops, using sensors to monitor speed and torque and adjust the power accordingly, creating a closed-loop system for precise control.

Think of cruise control in your car. It's a type of motor controller, maintaining a consistent speed despite changes in terrain or load. DC motor controllers do the same thing for your projects, ensuring consistent and reliable performance. Without one, you're at the mercy of voltage fluctuations, load variations, and potential overheating, all of which can lead to inconsistent results and a shortened motor lifespan.

One key function of a DC motor controller is protection. They can detect overcurrent conditions, which can happen if the motor is overloaded or encounters an obstruction, and shut down the motor to prevent damage. This is like a circuit breaker in your home, preventing electrical fires. Without this protection, you risk frying your motor and potentially causing other components in your circuit to fail.

Different controllers offer different functionalities. Some allow you to reverse the direction of the motor, others provide precise speed control through Pulse Width Modulation (PWM), and still others offer advanced features like current limiting and regenerative braking. The choice of controller depends entirely on the specific requirements of your application. Are you building a robot that needs to navigate a complex environment? You'll need a sophisticated controller. Simply spinning a fan? A basic one will probably suffice.

Types of DC Motor Controllers

3. From Simple to Sophisticated

Just like there are different types of cars, there are different types of DC motor controllers, each suited for specific applications and budgets. Understanding the various options available is crucial in selecting the right one for your project. There are simple potentiometers, H-bridges, dedicated motor driver ICs, and even microcontroller-based controllers.

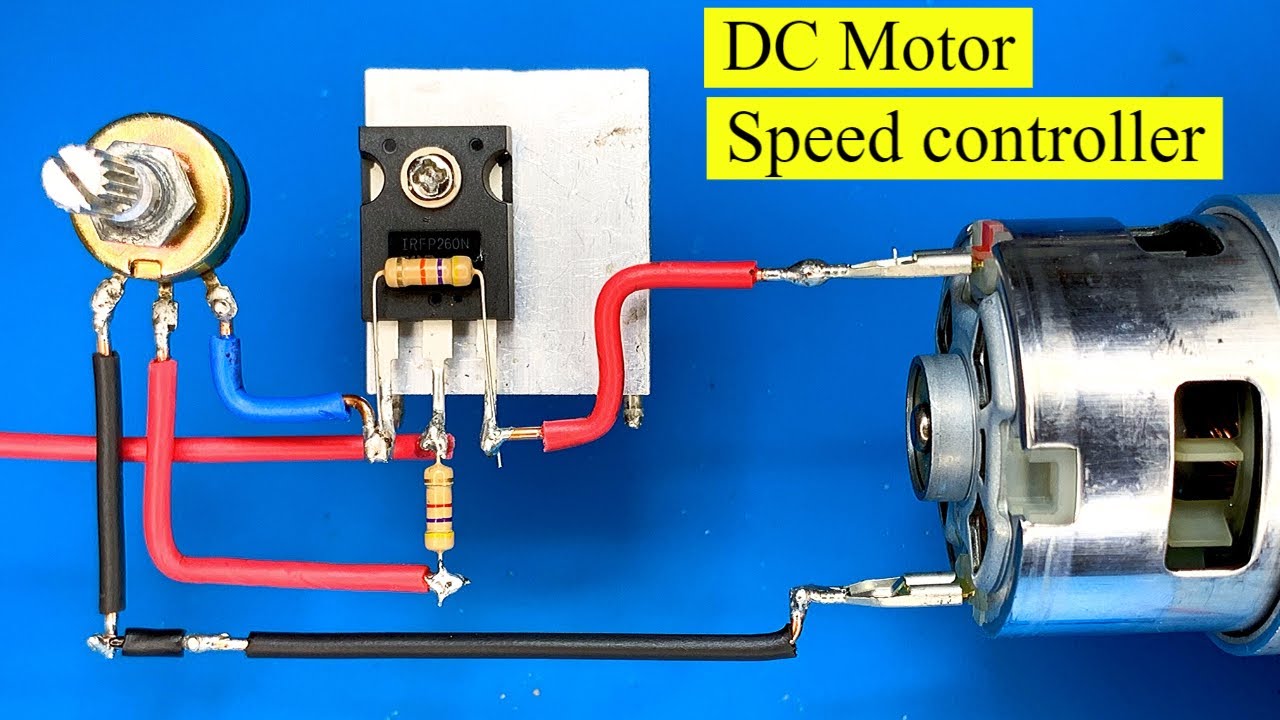

The simplest form of DC motor control involves a potentiometer (a variable resistor). By adjusting the potentiometer, you can vary the voltage applied to the motor, thus controlling its speed. This is a cheap and easy solution, but it's not very efficient and doesn't offer much in the way of precision or protection. Imagine dimming a light bulb — similar concept, but for a motor.

H-bridges are circuits that allow you to reverse the direction of the motor. They essentially swap the polarity of the voltage applied to the motor, causing it to spin in the opposite direction. H-bridges are fundamental building blocks in many motor control systems, enabling robots to move forward and backward, or automated systems to perform reciprocating actions.

Dedicated motor driver ICs (Integrated Circuits) are chips specifically designed to control DC motors. They often incorporate features like overcurrent protection, thermal shutdown, and PWM control. These ICs simplify the design of motor control circuits and provide a more robust and reliable solution compared to discrete components. Theyre like pre-packaged solutions that handle all the messy details for you.

For more advanced control, you can use a microcontroller to implement custom control algorithms. Microcontrollers can read sensor data, implement PID (Proportional-Integral-Derivative) control, and communicate with other devices. This approach offers the greatest flexibility and control, but it also requires more programming and electronics expertise. It's like writing your own symphony instead of just playing a pre-written tune.

How To Make Simple Dc Motor Speed Control Circuit, Electronics Projects

Benefits of Using DC Motor Controllers

4. Why Bother with a Controller?

Beyond just making the motor spin, a DC motor controller brings a plethora of advantages to the table. Improved efficiency, extended motor lifespan, and precise control are just a few of the benefits that justify the added complexity and cost. Think of it as investing in preventative maintenance for your motor, avoiding costly repairs down the road.

Controllers enable precise speed control, which is crucial for applications requiring consistent and repeatable performance. Imagine a conveyor belt in a factory; consistent speed is essential for efficient production. By using a controller, you can maintain the desired speed regardless of load variations or voltage fluctuations. Without it, you're relying on luck and hoping for the best, not exactly a recipe for success.

Many controllers offer overcurrent protection, preventing damage to the motor and other components in your circuit. Overcurrent can occur due to overloading, short circuits, or mechanical blockages. By shutting down the motor in these situations, the controller prevents overheating and potential fires. This is like having an automatic emergency brake for your motor, preventing catastrophic failures.

By optimizing the voltage and current supplied to the motor, controllers can improve its efficiency. This means the motor will consume less power for the same amount of work, saving energy and extending battery life in portable applications. Furthermore, controllers can implement regenerative braking, which recovers energy during deceleration and feeds it back into the power supply, further enhancing efficiency. It's like recycling energy instead of wasting it.

Controllers can also extend the lifespan of the motor by reducing stress and wear. By preventing overcurrent and overheating, and by providing smooth start and stop sequences, the controller minimizes mechanical and electrical stress on the motor's components. Think of it as providing a comfortable and stress-free environment for your motor, allowing it to operate reliably for longer.

Choosing the Right Controller

5. What to Consider Before Buying

Selecting the appropriate DC motor controller for your project is paramount. It's not just about picking the fanciest or the cheapest option; it's about finding the one that best matches your needs. Consider the motor's voltage and current requirements, the desired level of control, the complexity of your application, and your budget. It's like choosing the right tool for the job; a hammer won't work for screwing in a screw.

First, ensure that the controller is rated for the voltage and current of your motor. Using a controller with insufficient current capacity can lead to overheating and failure. Exceeding the voltage rating can damage the controller itself. Always check the specifications carefully and err on the side of caution. It's better to have a controller that's slightly over-rated than one that's undersized.

Next, consider the level of control you need. Do you simply need to turn the motor on and off? Or do you need precise speed control, directional control, and current limiting? The more features you need, the more complex (and potentially expensive) the controller will be. It's like choosing between a basic flip phone and a smartphone; both can make calls, but one offers a whole lot more.

Think about the environment in which the motor will be operating. Will it be exposed to extreme temperatures, humidity, or vibration? If so, you'll need a controller that's designed to withstand these conditions. Also, consider the size and weight of the controller, especially if you're working on a portable or space-constrained application. You wouldn't want to use a massive controller in a tiny drone, for example.

Finally, don't forget about your budget. DC motor controllers range in price from a few dollars to hundreds of dollars. While it's tempting to go for the cheapest option, it's important to consider the long-term cost of reliability and performance. A cheap controller that fails prematurely or doesn't provide adequate protection can end up costing you more in the long run. It's like buying a cheap pair of shoes that fall apart after a few weeks; investing in a quality pair will save you money in the long run.

FAQ

6. Your Burning Questions Answered!

Still got questions swirling around your head? Let's tackle some of the most common queries about DC motor controllers.

Q: Can I control a DC motor directly from an Arduino?

A: Yes, but carefully! An Arduino's digital pins can only supply a small amount of current. For small motors, you might get away with it using a transistor as a switch. However, for anything substantial, you'll need a dedicated motor driver that can handle the motor's current and voltage requirements. Bypassing the driver is a surefire way to let the smoke out of your Arduino, and nobody wants that!

Q: What is PWM and why is it important for DC motor control?

A: PWM stands for Pulse Width Modulation. It's a technique used to control the average power delivered to the motor by rapidly switching the voltage on and off. By varying the "duty cycle" (the proportion of time the voltage is on), you can effectively control the motor's speed. PWM is far more efficient than simply reducing the voltage with a resistor, and it allows for smoother and more precise speed control.

Q: My motor is overheating. Is it the controller's fault?

A: Not necessarily, but it could be. Overheating can be caused by several factors, including overloading the motor, insufficient cooling, or a faulty controller. First, make sure the motor isn't being asked to do more than it's designed for. Check for any mechanical obstructions. If those aren't the issue, the controller might not be providing adequate current limiting or might be malfunctioning. It's always a good idea to double-check the controller's settings and specifications.