Cant Miss Takeaways Of Tips About What Does ACSR Mean In Wire

Cable Guide ACSR Conductor

Decoding ACSR

1. What's the Big Deal with ACSR Anyway?

Ever squinted at those thick power lines stretching across the landscape and wondered what they're made of? Or perhaps you're planning a DIY electrical project and stumbled upon the term "ACSR wire." Well, ACSR isn't some super-secret government acronym, though it sounds like it could be! It stands for Aluminum Conductor Steel Reinforced. Essentially, it's a specific type of high-capacity, high-strength stranded cable frequently used in overhead power lines.

Think of it like this: imagine trying to build a bridge out of spaghetti. Plain spaghetti would snap under its own weight, right? Now imagine putting steel cables inside that spaghetti bridge. Suddenly, it's much stronger and can handle a lot more! That's kinda what ACSR is doing the steel provides the strength, while the aluminum handles the electricity.

The brilliance of ACSR lies in its combination of properties. Aluminum is a fantastic conductor of electricity, much lighter than copper (another common conductor), which means it doesn't weigh down the power lines as much. Steel, on the other hand, provides the necessary tensile strength to support the weight of the aluminum and withstand the forces of wind, ice, and general atmospheric shenanigans. Its like a superhero team-up for electrical conductivity!

Without the steel core, the aluminum alone would sag too much between poles, causing all sorts of problems. And without the aluminum, well, you wouldnt be getting much electricity flowing! So, the steel core acts as the backbone, allowing for longer spans between supporting structures, which reduces the number of poles needed — saving money and resources in the long run.

What Is An ACSR Conductor? Explain Its Types And Advantages

Why Not Just Use Copper Wire?

2. The Copper vs. Aluminum Showdown

That's a fair question! Copper is an excellent conductor, arguably even better than aluminum. So why isn't it used in overhead power lines everywhere? The main reason boils down to cost and weight. Copper is significantly more expensive than aluminum. When you're talking about thousands of miles of power lines, that price difference adds up very quickly.

Furthermore, copper is much heavier than aluminum. This means that copper wires would require stronger support structures and shorter spans between poles, again increasing the overall cost and complexity of power line construction. Think about the logistics of hauling tons of copper cable across vast distances — it's a logistical nightmare and a financial burden.

Aluminum, therefore, offers a sweet spot between conductivity, cost, and weight. While it doesn't conduct quite as well as copper, the difference is often negligible in many applications, especially when considering the significant cost savings. Plus, the addition of the steel core provides the necessary strength to compensate for aluminum's lower tensile strength compared to copper. It's all about finding the right balance for the job at hand.

So, while you might find copper wire in your house wiring, don't expect to see it strung between massive pylons any time soon. ACSR is the reigning champion of overhead power transmission for a reason — it's practical, efficient, and relatively affordable.

Inside ACSR

3. Deconstructing the ACSR Cable

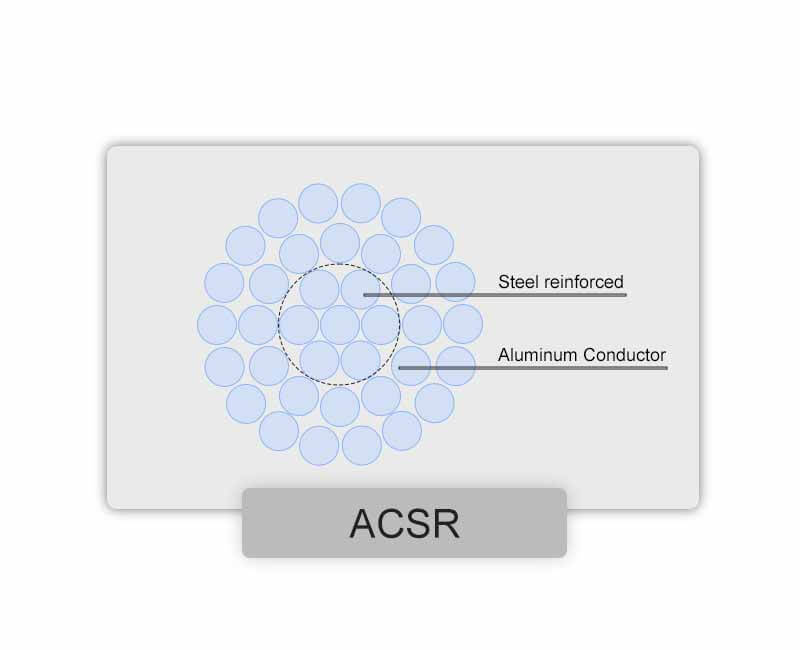

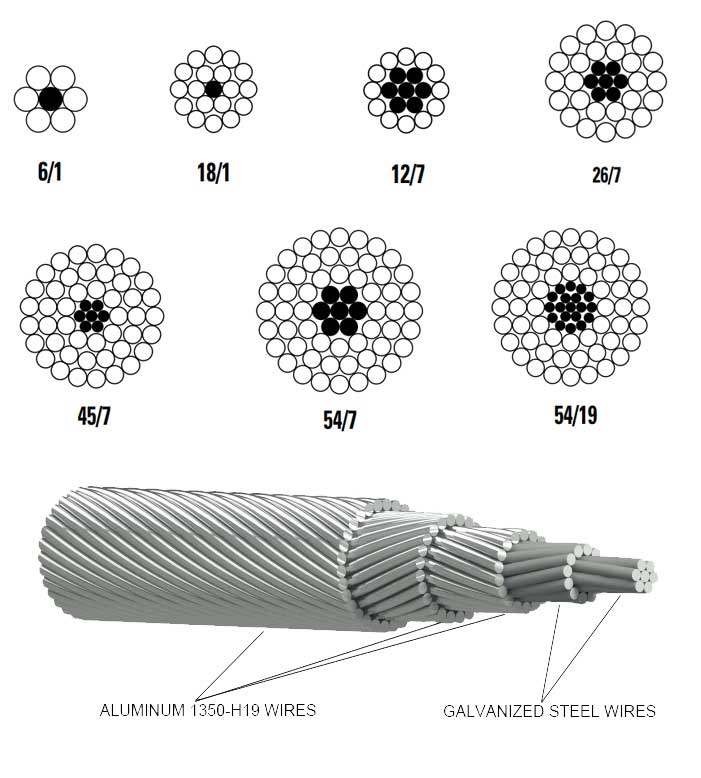

ACSR wire isn't just a solid chunk of metal; it's a carefully constructed cable made up of multiple layers. Typically, it consists of a central steel core surrounded by one or more layers of aluminum strands. The steel core is usually galvanized to protect it from corrosion, ensuring a longer lifespan for the cable.

The number of aluminum strands and the diameter of the steel core can vary depending on the specific application and the amount of current the cable needs to carry. Larger cables with more aluminum strands can handle higher currents, while a stronger steel core can support longer spans. Its all about tailoring the cable to the specific requirements of the power line.

The aluminum strands are typically made of EC (Electrical Conductor) grade aluminum, which is specifically designed for electrical applications. This type of aluminum has a high purity and excellent conductivity. The strands are also often treated with a lubricant to reduce friction and prevent corrosion between the aluminum and steel layers.

Think of it as a carefully engineered sandwich. The steel core provides the structural integrity, the aluminum provides the electrical conductivity, and the lubricant ensures everything plays nicely together for decades to come. The layers are often spiraled around each other to provide better flexibility and strength, allowing the cable to withstand bending and twisting forces without breaking.

ACSR

4. Where Else Might You Find ACSR?

While ACSR is most commonly associated with overhead power lines, it can also be used in other applications where high strength and good conductivity are required. For example, it's sometimes used in grounding cables and in some specialized electrical equipment.

However, it's important to note that ACSR is generally not suitable for indoor wiring or applications where flexibility is paramount. The steel core makes it relatively stiff compared to other types of electrical wire, and it's not designed for the tight bends and complex routing often required in building wiring. It's really more of a "heavy-duty" outdoor sort of wire.

Consider also, that while you might find smaller-gauge ACSR in more niche application, youre generally not going to be using it for running electricity to your coffee maker. Its strength and efficiency are best leveraged for high-voltage, long-distance power transmission. That's where it truly shines.

So, while you might not encounter ACSR in your everyday life beyond seeing it overhead, it's worth knowing that this specialized wire plays a crucial role in delivering electricity to homes and businesses around the world. Next time you flick on a light switch, remember the unsung hero — ACSR!

Safety First

5. A Word of Caution

Working with any electrical wiring can be dangerous, and ACSR is no exception. It's crucial to follow all safety precautions and regulations when handling or installing ACSR wire. Always de-energize the circuit before working on any electrical components, and use appropriate personal protective equipment (PPE) such as gloves and safety glasses.

Because ACSR contains a steel core, it can be more difficult to cut and strip than other types of wire. Special tools designed for cutting and stripping ACSR are recommended to ensure a clean and safe connection. Never use dull or damaged tools, as they can increase the risk of injury or damage to the wire.

If you're not comfortable working with electrical wiring, it's always best to hire a qualified electrician. They have the knowledge, experience, and tools to handle electrical installations safely and efficiently. Don't risk your safety or the safety of others by attempting electrical work that you're not qualified to perform.

Remember, electricity is powerful and unforgiving. Respect it, take precautions, and always prioritize safety when working with ACSR or any other electrical wiring. Your well-being is far more important than saving a few bucks on a DIY project. And if in doubt, call a professional!

FAQ

6. Your Burning Questions Answered

Let's tackle some common questions about ACSR wire to clear up any remaining confusion.

7. Q

A: Probably not. ACSR is designed for overhead power transmission and is not typically suitable for indoor wiring due to its stiffness and the need for specialized connectors. Stick to standard NM-B (Romex) cable for your home wiring needs.

8. Q

A: Yes, ACSR is recyclable! The aluminum and steel components can be separated and recycled, making it an environmentally friendly choice.

9. Q

A: The lifespan of ACSR wire can vary depending on environmental conditions and maintenance practices, but it typically lasts for several decades. Regular inspections and maintenance can help extend its lifespan.

10. Q

A: The steel core of ACSR is typically galvanized to prevent rust. However, over time, the galvanization can wear away, leading to corrosion. Regular inspections can help identify and address any corrosion issues before they become severe.