Fine Beautiful Info About What Is A Y Splice

Electrical Wiring Splices Types Of Wire Joints

Demystifying the Y Splice

1. What exactly is a Y splice and why should I care?

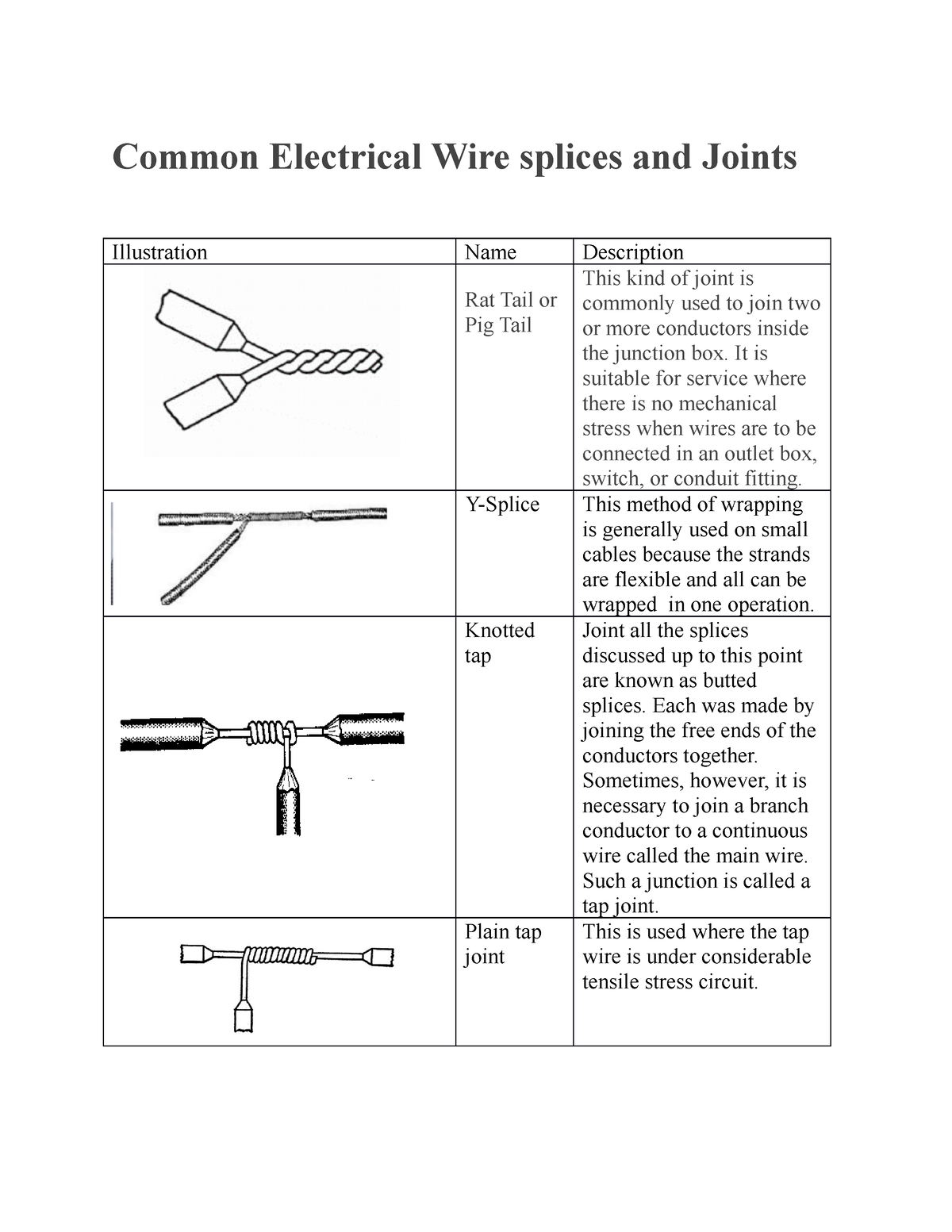

Ever found yourself needing to split a single wire into two, like branching off a water hose? That's where the humble Y splice comes to the rescue! In its simplest form, a Y splice is a method of joining electrical wires in a 'Y' shape. Instead of just connecting wires end-to-end (like a straight splice), a Y splice creates a branch, allowing you to distribute power or signals in two different directions from a single source. Think of it like a fork in the road for electricity!

The "Y" shape provides a more robust and secure connection compared to simply twisting wires together and hoping for the best. It distributes the electrical load more evenly, reducing the risk of overheating or loose connections, which can lead to all sorts of electrical gremlins causing trouble.

You'll find Y splices being used in all sorts of applications, from automotive wiring to home electrical projects. They're particularly useful when you need to tap into an existing circuit without interrupting the main power flow. For example, you might use a Y splice to add an extra light fixture to a circuit or to power a new accessory in your car.

So, while it might not be the most glamorous component, the Y splice is a reliable workhorse in the world of electrical connections. Knowing how and when to use one can save you time, frustration, and even prevent potential electrical hazards. We'll delve deeper into its uses and proper techniques shortly.

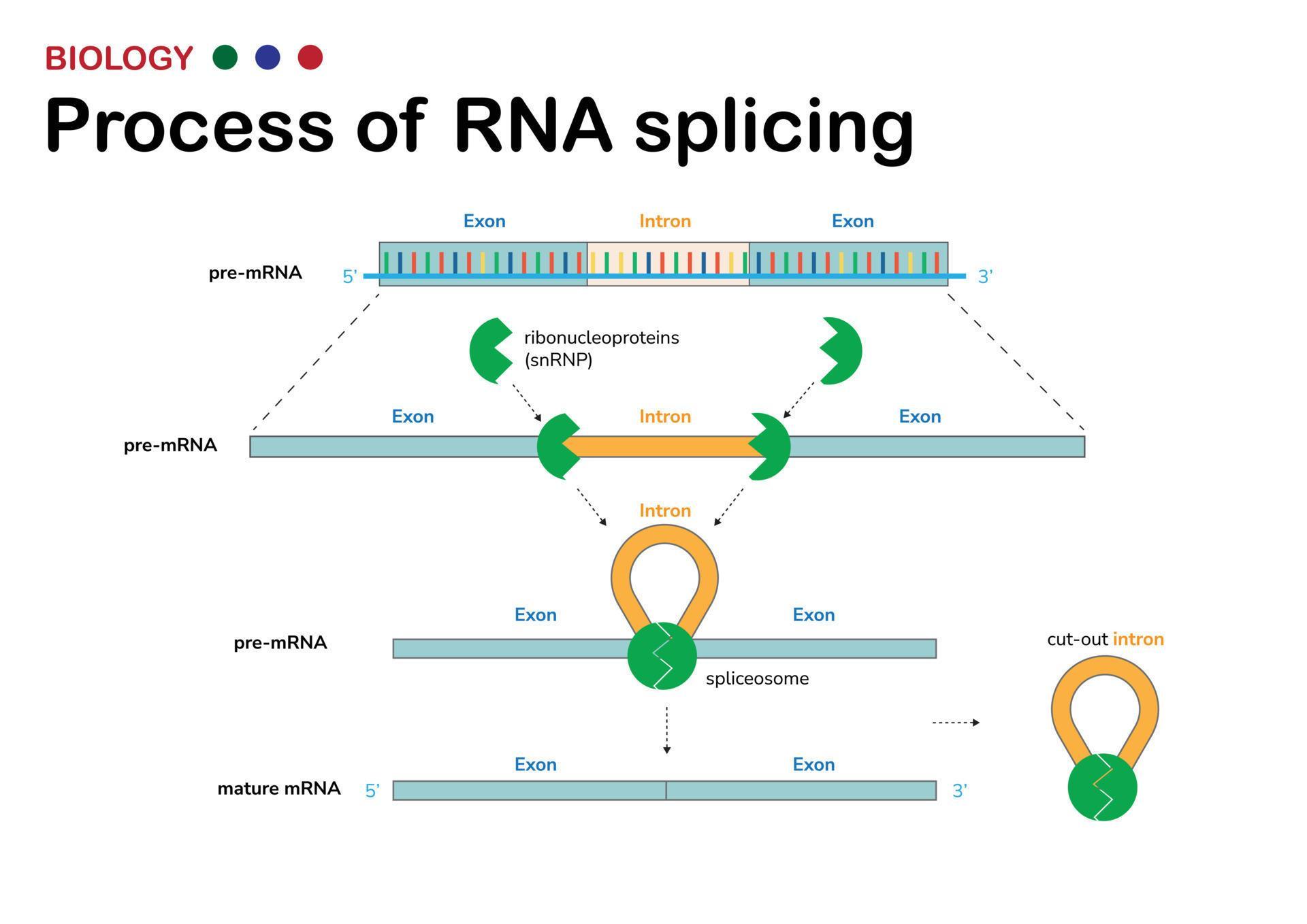

How DNA Will Be Translated To RNA ChatSlide

When Would You Actually Use a Y Splice? Real-World Scenarios

2. Practical applications where Y splices shine.

Okay, so you know what a Y splice is, but when do you actually need one? Let's consider a few scenarios where these little connectors can be incredibly useful.

Automotive Adventures: Imagine you're installing new fog lights on your car and you want to tap into the existing headlight circuit. A Y splice allows you to do this cleanly and safely, providing power to your fog lights without cutting or disrupting the original headlight wiring. It's much better than just wrapping wires together with electrical tape — trust me on that one!

Home Electrical Hacks (with caution!): Adding a new outlet to an existing circuit can be a prime candidate for a Y splice. Let's say you have a string of holiday lights you want to extend, and there's only one outlet available. You could use a Y splice to split the power and add a second outlet for your lights. Important safety note: Always turn off the power at the breaker box before working with electrical wiring. And if you're not comfortable working with electricity, it's always best to call a qualified electrician.

Low-Voltage Landscapes: Outdoor lighting systems often rely on Y splices to distribute power to multiple lights from a single transformer. This allows for a neat and organized wiring layout, preventing a tangled mess of wires in your garden. Plus, it makes troubleshooting easier if something goes wrong down the line.

Electronics Projects: Hobbyists and electronics enthusiasts often use Y splices in their projects to create branching circuits or to connect multiple components to a single power source. Think of adding multiple LEDs to a single power supply in your custom-built robot.

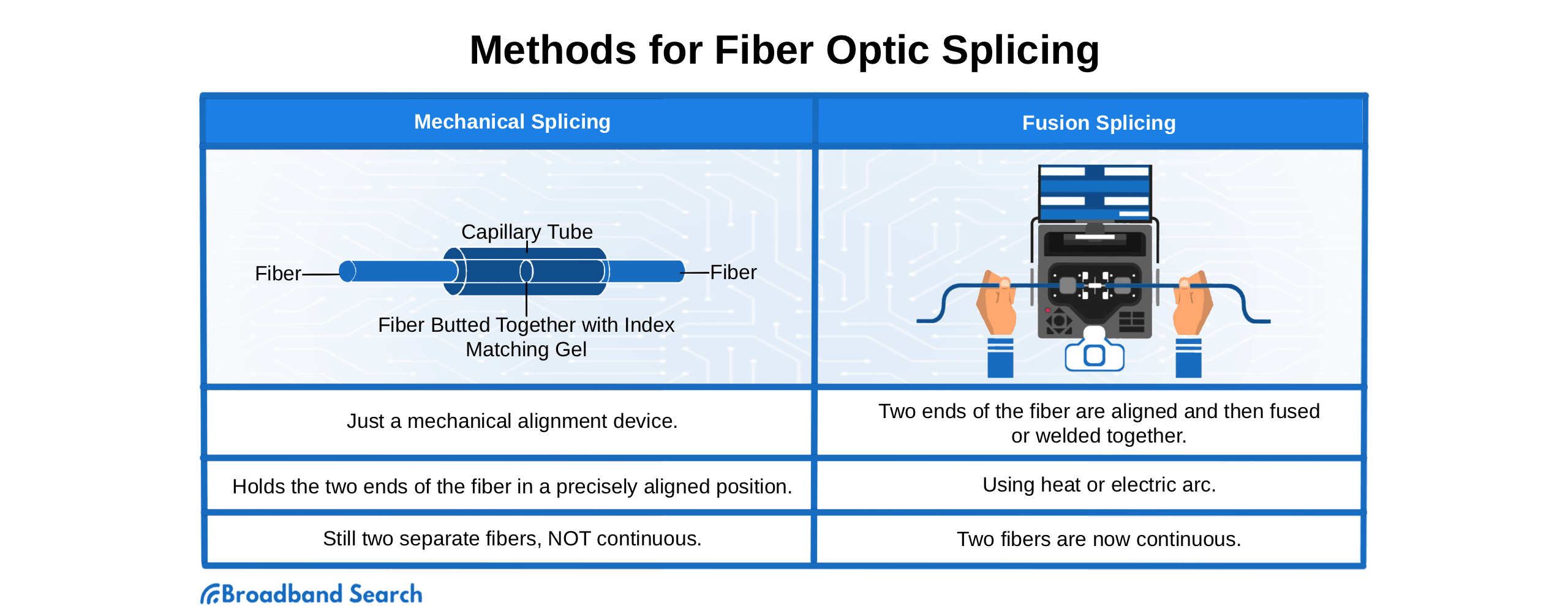

How Anyone Can Splice Fiber Optic Cable BroadbandSearch

How to Create a Solid Y Splice

3. Making secure and reliable Y splice connections.

Alright, let's get down to the nitty-gritty (oops! Almost slipped up there — let's say "specifics") of creating a Y splice. While the exact method can vary depending on the wires you're working with and your personal preference, here's a general step-by-step guide to get you started.

Step 1: Gather Your Supplies: You'll need wire strippers, electrical tape (or heat shrink tubing), and the wires you want to splice. If you're using solder, you'll also need a soldering iron and solder. Crimping tools and connectors might also be needed depends on the type of Y-Splice you are aiming for.

Step 2: Strip the Wires: Carefully strip the insulation from the ends of all three wires (the main wire and the two branches) to expose the bare copper. Be careful not to nick or damage the wire itself, as this can weaken the connection. About half an inch of exposed wire is usually sufficient.

Step 3: Twist the Wires: Take the two branch wires and twist them together around the main wire. Ensure the exposed copper is completely covered and that the connection is tight and secure. You can use pliers to help you get a good grip and twist them firmly.

Step 4: Secure the Connection: This is where you have a few options. You can wrap the connection tightly with electrical tape, making sure to overlap each layer. Alternatively, you can use heat shrink tubing, which provides a more professional and durable finish. If you prefer, you can solder the connection for maximum conductivity and strength. Just be sure to let the solder cool completely before moving on.

Step 5: Insulate the Splice: Whether you used electrical tape or heat shrink tubing, make sure the entire splice is completely insulated. This will prevent short circuits and protect the connection from moisture and corrosion. Double-check that there are no exposed wires before moving on.

Diffe Types Of Wire Splices Wiring Draw

Choosing the Right Materials

4. Selecting appropriate materials and prioritizing safety.

Using the right materials is just as important as using the right technique. Choosing the wrong wire gauge or connector can lead to overheating, electrical fires, or just plain failure. So, let's talk about some key considerations.

Wire Gauge Matters: The gauge of the wire determines how much current it can safely handle. Using a wire that's too thin for the application can cause it to overheat and melt the insulation, creating a fire hazard. Always check the current rating of the circuit and choose a wire gauge that's appropriate. A general rule of thumb is to use the same gauge wire for all parts of the splice. So, if the main wire is 14-gauge, use 14-gauge wire for the branches as well.

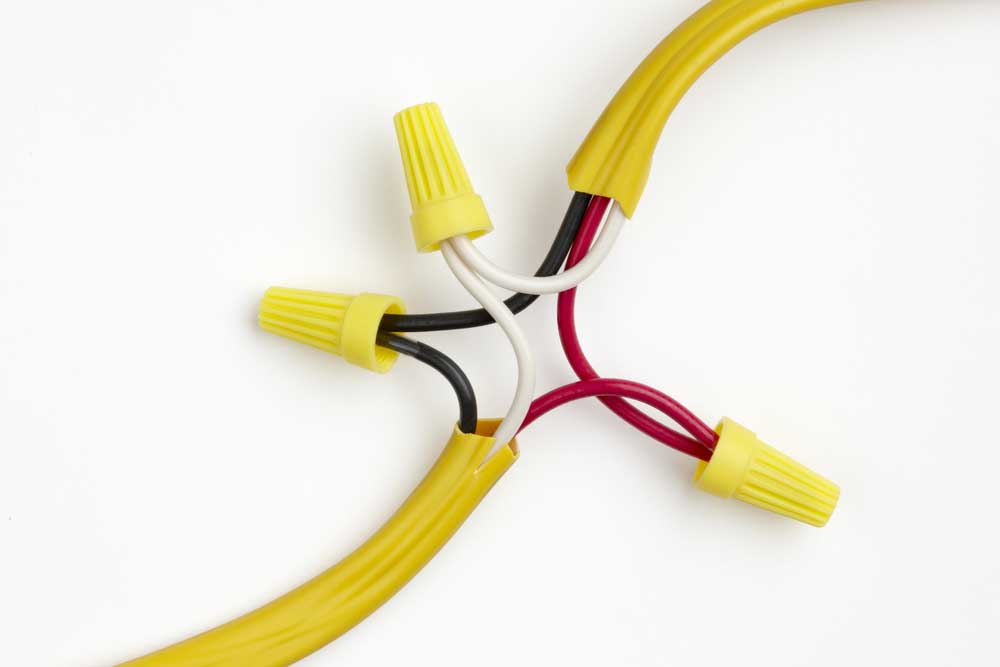

Connector Choices: There are various types of connectors available for making Y splices, each with its own advantages and disadvantages. Some common options include crimp connectors, solder sleeves, and twist-on wire connectors (also known as "wire nuts"). Crimp connectors are easy to use and provide a secure connection, but they require a crimping tool. Solder sleeves provide a very strong and reliable connection, but they require soldering skills. Twist-on wire connectors are convenient for quick connections, but they may not be as reliable as other options.

Safety First: Working with electricity can be dangerous, so it's essential to take precautions. Always turn off the power at the breaker box before working on any electrical wiring. Wear safety glasses to protect your eyes from flying debris. And if you're not comfortable working with electricity, it's always best to call a qualified electrician. Remember, your safety is more important than saving a few bucks.

Insulation is Key: No matter which method you choose, always ensure that the splice is properly insulated to prevent short circuits. Electrical tape is a common choice, but heat shrink tubing provides a more durable and professional-looking finish. Make sure the insulation completely covers the exposed wires and that there are no gaps or cracks.

The 'simple' Splice Connection IDEA StatiCa

Troubleshooting Common Y Splice Issues

5. Identifying and resolving problems with Y splice connections.

Even with the best techniques and materials, things can sometimes go wrong. Here are some common issues you might encounter with Y splices and how to troubleshoot them.

Loose Connections: A loose connection is one of the most common causes of problems with Y splices. This can be due to improperly twisted wires, loose connectors, or corrosion. If you suspect a loose connection, turn off the power and carefully inspect the splice. Retighten the wires or replace the connector if necessary. Make sure the wires are securely fastened and that there is no corrosion or oxidation.

Overheating: Overheating can occur if the wire gauge is too small for the current load or if the connection is not making good contact. This can damage the insulation and even cause a fire. If you notice any signs of overheating, such as melted insulation or a burning smell, turn off the power immediately and inspect the splice. Replace the wire with a heavier gauge or improve the connection.

Short Circuits: A short circuit occurs when bare wires come into contact with each other or with a grounded surface. This can cause a sudden surge of current, tripping a breaker or blowing a fuse. If you suspect a short circuit, turn off the power and carefully inspect the splice for any exposed wires. Repair any damaged insulation and ensure that the wires are properly separated.

Intermittent Problems: Sometimes, Y splices can cause intermittent problems that are difficult to diagnose. This can be due to loose connections that only make contact occasionally or to corrosion that interferes with the current flow. If you're experiencing intermittent problems, try wiggling the wires or tapping on the splice to see if it affects the circuit. If so, you likely have a loose connection or corrosion that needs to be addressed.