Unbelievable Tips About What Is DK In PCB

What's the Deal with DK in PCBs? Unraveling the Mystery

1. Demystifying DK

Okay, let's clear something up right away. When we're talking about "DK" in the world of Printed Circuit Boards (PCBs), we're definitely not talking about Donkey Kong. Although, a PCB that could run that classic game flawlessly would be pretty impressive! Instead, "DK" is shorthand for something a little more technical: Dielectric Constant.

Now, the dielectric constant might sound like something straight out of a science textbook — and, well, it kind of is. But don't let that scare you off! It's a crucial property of the materials that make up your PCB, and understanding it can help you grasp how well your board will perform, especially at high frequencies. Think of it as the material's ability to store electrical energy. A higher DK means it can store more energy, which can affect signal speed and overall circuit behavior. Imagine trying to run a high-speed internet connection through old copper wiring; its similar in that the material impacts performance.

Why should you even care? Because the DK value affects signal integrity. A miscalculated DK can lead to signal loss, impedance mismatches, and ultimately, a circuit that doesn't quite do what you intended. Picture it as trying to bake a cake without knowing the right oven temperature; you might end up with a burnt offering or a gooey mess! Knowing your DK value ensures that your signal travels predictably and reliably across the board.

In simpler terms, the dielectric constant influences the speed at which electrical signals travel through the insulating material between the copper traces on your PCB. It's a key factor in determining the performance characteristics of your circuit, especially at higher frequencies. Selecting the right material with the appropriate DK value is critical for ensuring signal integrity and preventing performance issues. This is one aspect where good design leads to good performance, and poor planning can lead to unexpected results.

The Dielectric Constant Deep Dive

2. Understanding the Nuances of DK

So, we know DK stands for Dielectric Constant, but what exactly does that mean in practice? Think of it like this: the dielectric constant tells us how much the electric field within a material is reduced compared to the electric field in a vacuum. In other words, it's a measure of how well a material can insulate against an electric field. A material with a high DK will reduce the electric field more than a material with a low DK.

This might sound complicated, but the implications are quite practical. A higher DK allows for smaller component spacing. Imagine designing a really compact, powerful smartphone; using materials with a higher DK would enable you to squeeze more functionality into a smaller space. Conversely, a lower DK is often preferred in high-speed applications to minimize signal loss and improve signal propagation speed.

However, DK isn't a fixed value. It can vary depending on several factors, including temperature, frequency, and even the specific manufacturing process. This is why it's crucial to consult the material's datasheet and consider these variations when designing your PCB. You wouldnt want your carefully designed circuit to malfunction simply because the DK value shifted unexpectedly at operating temperature!

Furthermore, DK isn't the only dielectric property you need to consider. The Dielectric Loss Tangent (often abbreviated as Df or tan ) is another important parameter. It represents the energy lost as heat within the dielectric material. A lower Df is generally desirable, as it indicates less signal loss and better overall performance. Choosing materials that balance both DK and Df is essential for optimizing your PCB design.

Do You Need Low Dk PCB Materials? YouTube

DK and PCB Materials

3. Material Selection Matters

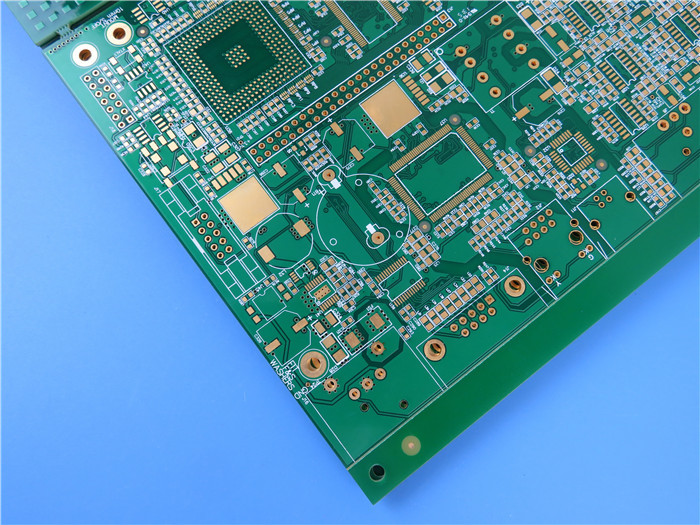

Now that you understand what DK is and why it's important, let's talk about how it relates to different PCB materials. Various materials are used in PCB manufacturing, each with its own unique DK value. The choice of material depends on the specific requirements of the application, such as operating frequency, temperature range, and signal integrity needs.

For example, FR-4 is a commonly used material with a relatively low cost and good overall performance. However, its DK value can vary depending on the specific formulation, typically ranging from 4.2 to 4.8. This makes it suitable for a wide range of applications, but it might not be the best choice for very high-frequency circuits where signal loss is a major concern. It's like choosing an all-purpose tire for your car; it's good for everyday driving, but not ideal for racing.

For high-frequency applications, materials like PTFE (Teflon) or ceramics are often preferred. These materials have lower DK values and lower loss tangents, resulting in better signal integrity and improved performance at higher frequencies. However, they also tend to be more expensive than FR-4. It's a trade-off between performance and cost, and the optimal choice depends on the specific requirements of the project. Imagine choosing a specialized racing tire; it's more expensive, but it delivers superior performance on the track.

Beyond the base material, the resin used to bond the layers of the PCB together also plays a role in the overall DK. Different resins have different dielectric properties, and the selection of the right resin can further optimize the performance of the board. It's like choosing the right type of glue for a woodworking project; the glue not only holds the pieces together but also affects the overall strength and durability of the finished product. Always consult datasheets and work with experienced PCB manufacturers to ensure you're making the best material choices for your design.

The Impact of DK on High-Frequency Applications

4. Why DK is Critical for Speed

In the realm of high-frequency applications, the dielectric constant, DK, takes center stage. Think of those lightning-fast 5G networks, or the intricate circuitry within modern radar systems. These demanding scenarios require materials with precisely controlled DK values to ensure signal integrity and minimize losses. A slight deviation from the expected DK can lead to significant performance degradation. Its akin to a tiny pebble causing a major detour on a high-speed race track.

High-frequency signals are particularly sensitive to impedance mismatches. Impedance, in simple terms, is the resistance to the flow of alternating current. When the impedance changes abruptly along the signal path, reflections occur, causing signal distortion and energy loss. The DK of the PCB material directly influences the impedance, and therefore, any variations in DK can lead to these undesirable mismatches. You want to keep your signals running smooth, not bouncing all over the place!

To mitigate these issues, designers often employ techniques like impedance control. This involves carefully selecting materials with specific DK values and precisely controlling the dimensions of the copper traces. Specialized software tools are used to simulate the signal behavior and optimize the design for minimal reflections. It's like fine-tuning a musical instrument; you adjust the parameters to achieve the desired sound, and in this case, the desired signal performance.

Furthermore, at very high frequencies, the surface roughness of the copper traces can also become significant. Rougher surfaces can increase signal loss and affect the effective DK. Therefore, advanced manufacturing techniques are often used to create smooth copper surfaces, further improving signal integrity. Ultimately, achieving optimal performance in high-frequency applications requires a holistic approach, considering material selection, design techniques, and manufacturing processes.

LowDk PCB Materials HighSpeed Design

Frequently Asked Questions (FAQs) About DK in PCBs

5. Your Burning Questions Answered

Still scratching your head about the whole DK thing? No worries! Here are some common questions that might help clarify things:

Q: What happens if I choose the wrong DK value for my PCB material?A: If you pick the wrong DK, it can lead to signal integrity problems, such as impedance mismatches, signal reflections, and increased signal loss. This can result in reduced performance, unreliable operation, or even complete circuit failure. Its like using the wrong type of fuel in your car; it might run, but it wont run well, and you risk damaging the engine.

Q: Where can I find the DK value of a specific PCB material?A: The DK value is typically specified in the material's datasheet, which is provided by the manufacturer. Look for terms like "dielectric constant," "relative permittivity," or "r." Keep in mind that the DK value may vary depending on the frequency and temperature, so make sure to check the datasheet for the relevant conditions. It's like reading the nutrition label on your food; it gives you the important information about what you're consuming.

Q: Is a higher or lower DK value generally better?A: It depends on the application. In some cases, a higher DK might be desirable for miniaturization or energy storage. In other cases, a lower DK is preferred for high-speed applications to minimize signal loss. There's no universally "better" value; it's all about choosing the right material for the specific requirements of your design. Think of it like choosing the right tool for the job; a hammer isn't always the best solution, and neither is a screwdriver.

Q: Does DK change over temperature?A: Yes, the dielectric constant is temperature-dependent. The datasheet from the material manufacturer will have the DK value changes over temperature. Its important to consider the operating temperature range of your application and select materials with stable DK values within that range.