Favorite Tips About What Is The Clearance For PCB 50V

Understanding PCB Clearance for 50V

1. Why Clearance Matters

Ever wondered why those little gaps exist on your printed circuit boards (PCBs)? They're not just there for decoration! They're crucial for safety, especially when dealing with voltage. Clearance, in the context of PCBs, refers to the shortest distance through air between two conductive parts. Think of it as a buffer zone that prevents electrical arcing, which is basically electricity taking a shortcut — not a good thing!

When we're talking about a 50V circuit, clearance becomes particularly important. While 50V might not sound like a lot compared to the wall socket, it's more than enough to cause problems if not handled correctly. Insufficient clearance can lead to shorts, component damage, and even fire hazards. No one wants their electronics to go up in smoke!

So, clearance isn't just about following regulations; it's about ensuring your devices function reliably and safely for their intended lifespan. It's a foundational principle of good PCB design and a cornerstone of electrical safety. Ignoring it is like skipping leg day at the gym — eventually, you'll pay the price.

Furthermore, keep in mind that environmental conditions can also impact the necessary clearance. Humid environments, for example, reduce the dielectric strength of air, meaning that arcing can occur at smaller distances. This is why factors like humidity and altitude are often considered in clearance calculations for critical applications.

2. The Magic Number

Alright, let's get down to brass tacks. What's the actual clearance distance you need for a 50V PCB? Unfortunately, there's no single universally agreed-upon answer. It depends on several factors, including the applicable safety standards (like IPC-2221), the environment, and the level of acceptable risk.

Generally, for basic applications and benign environments, a clearance of 0.25mm (approximately 0.01 inches) might be sufficient. However, it's always best to err on the side of caution. Consult the relevant standards or, even better, consult with an experienced PCB designer. They can help you determine the appropriate clearance based on your specific application and regulatory requirements.

Bear in mind that this number is a minimum! Factors like the altitude at which the device will operate (higher altitudes have thinner air, making arcing easier) can necessitate larger clearances. Also, if your board is going to be used in a particularly dirty or dusty environment, a wider clearance can help prevent conductive contaminants from bridging the gap between conductors.

Thinking about the long term reliability is important. A tiny hair-like copper fragment detaching and bridging two closely spaced tracks could cause failures down the line, so don't scrimp on clearance if the design allows for it.

3. Standards and Guidelines

Several standards and guidelines dictate PCB clearance requirements. The most prominent is IPC-2221, "Generic Standard on Printed Board Design." This standard provides valuable information on conductor spacing, creepage, and other critical design parameters. It offers tables and formulas to help you calculate the appropriate clearance based on voltage, coating, and other factors.

Other standards, like UL (Underwriters Laboratories) standards, may also apply depending on the intended application of your device. UL standards are particularly relevant for products that will be sold in North America. These standards often have very specific requirements for insulation and clearance.

It's your responsibility as a designer (or the responsibility of your design team) to determine which standards apply to your product and to ensure that your PCB design meets those standards. This might involve some research and potentially some testing. But it's a necessary step to ensure the safety and compliance of your device.

Don't just skim through the standards! Take the time to understand the reasoning behind the requirements. Knowing why a certain clearance is recommended will help you make better design decisions and potentially even identify situations where a slight deviation from the standard is acceptable (though always proceed with caution and documentation).

4. Factors That Influence Clearance Requirements

As we've mentioned, voltage is a primary factor, but it's not the only factor that influences clearance requirements. Let's take a closer look at some of the other key variables.

Environmental Conditions: As we touched upon earlier, humidity and altitude play a significant role. High humidity reduces the dielectric strength of air, meaning that electricity can arc across smaller gaps. High altitude has a similar effect due to the thinner air. Temperature can also be a factor, though typically to a lesser extent.

Pollution Degree: This refers to the amount of conductive contamination present in the environment. A PCB operating in a clean, dry environment will require less clearance than one operating in a dusty, oily environment. Pollution can significantly reduce the surface resistance of the board and increase the risk of tracking (the formation of a conductive path along the surface of the board).

Coating: Applying a conformal coating to your PCB can significantly increase the dielectric strength of the insulation, allowing for smaller clearances. However, the coating must be applied properly and be free of defects to provide reliable protection. Different coatings have different dielectric strengths, so choose one that is appropriate for your application and voltage levels.

Material Group: Different PCB materials have different tracking resistance properties. Materials are categorized into groups based on their Comparative Tracking Index (CTI) values. Higher CTI values indicate better tracking resistance, allowing for potentially smaller clearances. Check the CTI values in your design to avoid electrical leakage which can cause issues down the line.

5. Practical Tips for Achieving Adequate Clearance

So, you know why clearance is important and what factors influence it. Now, let's talk about some practical tips for actually achieving adequate clearance in your PCB designs.

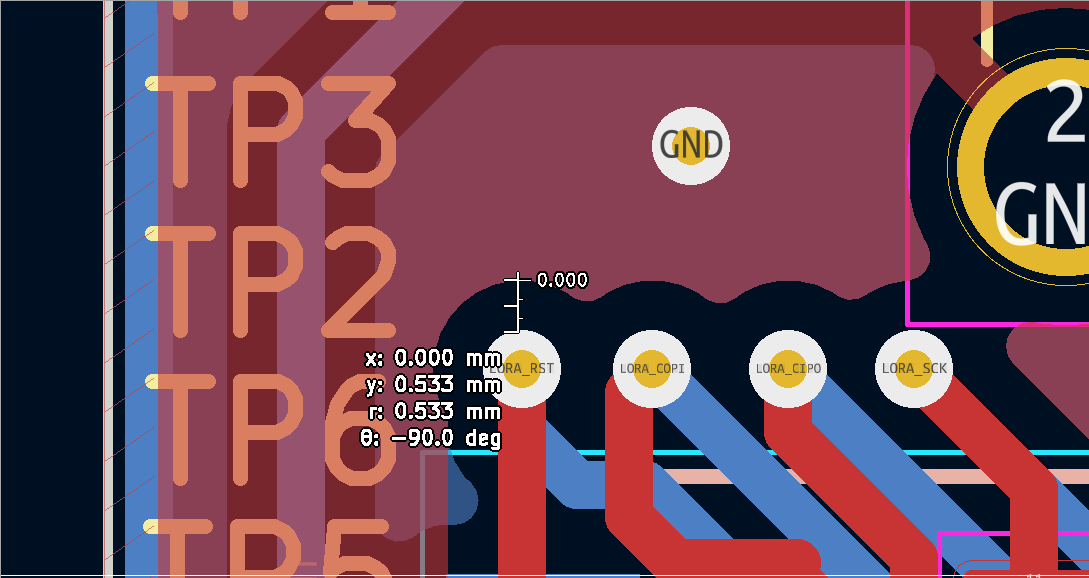

Use Your CAD Software: Modern PCB CAD software has built-in design rule checks (DRCs) that can automatically verify clearances. Configure these DRCs to match the appropriate standards for your application. This will help you catch clearance violations early in the design process, before they become expensive problems.

Think About Manufacturing: Consider the manufacturing tolerances of your PCB fabrication process. Even if your design meets the minimum clearance requirements, variations in the manufacturing process could result in clearances that are slightly smaller than intended. It's generally a good idea to add a little bit of margin to account for these variations. Communicate with your PCB manufacturer to understand their capabilities and limitations.

Component Placement: Carefully consider the placement of your components. Keep high-voltage components physically separated from low-voltage components. Orient components in a way that maximizes clearance. Avoid placing components too close to the edges of the board, where the risk of accidental contact is higher.

Layer Stackup: The layer stackup of your PCB can also influence clearance requirements. If you have high-voltage traces on multiple layers, ensure that there is adequate insulation between those layers. You can also use ground planes to shield high-voltage traces and reduce the risk of interference.

How To Achieve Optimal PCB Clearances Sierra Circuits Posted On The

Clearance And Creepage Distances Rules Calculation

PCB Creepage And Clearance Criteria In Designing Layout Kingford