Fabulous Tips About What Is The Purpose Of A Busbar

What Exactly Is a Busbar? Let's Demystify It

1. Breaking Down the Basics of a Busbar

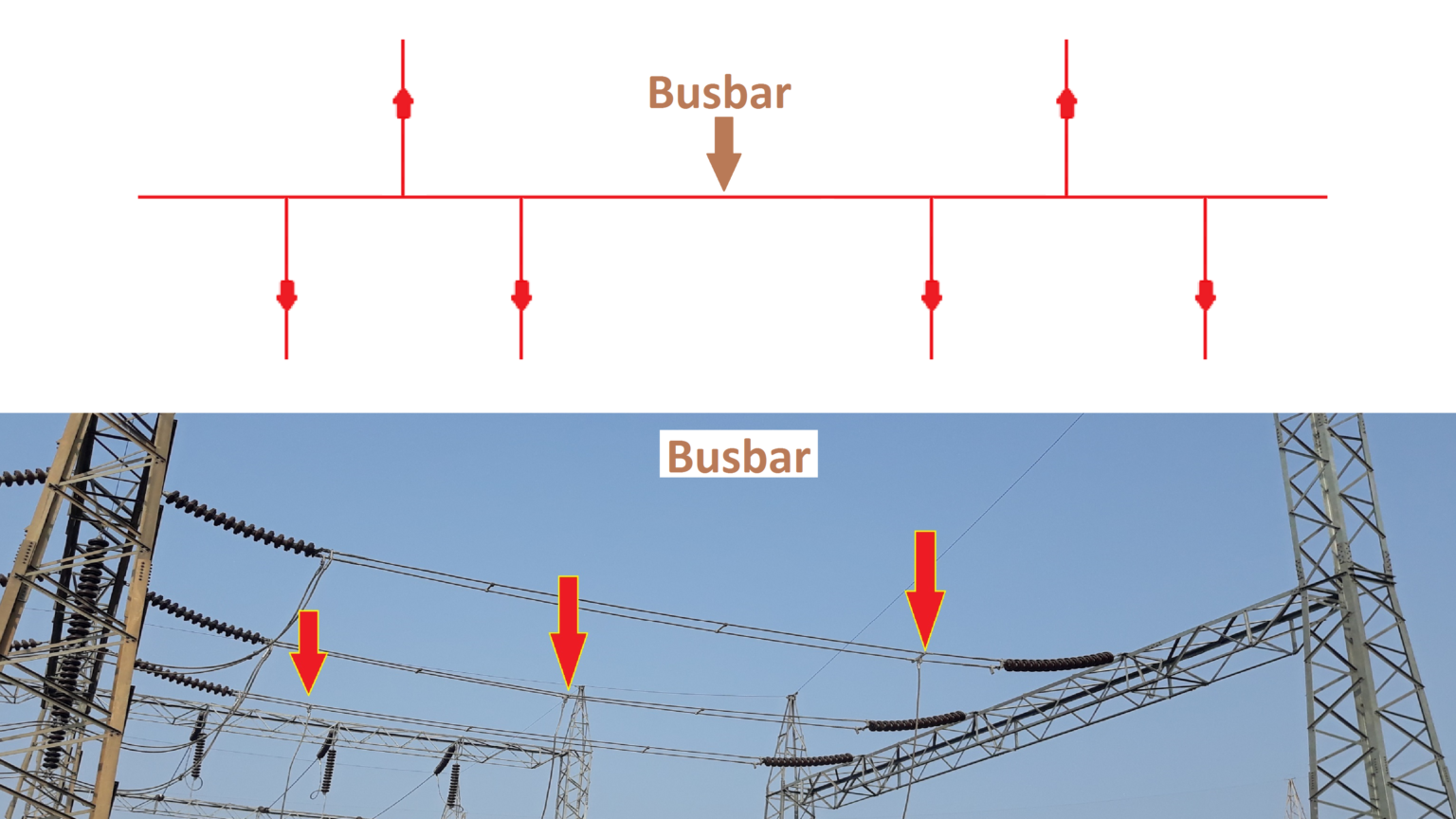

Okay, so you've probably heard the term "busbar" tossed around, especially if you're tinkering with anything electrical. But what is it, really? Think of it like the main power distribution highway in an electrical system. Instead of cars, we're talking electrons, and instead of highways, we're talking highly conductive materials, usually copper or aluminum. It's a crucial component, acting as a central collection and distribution point for electrical current.

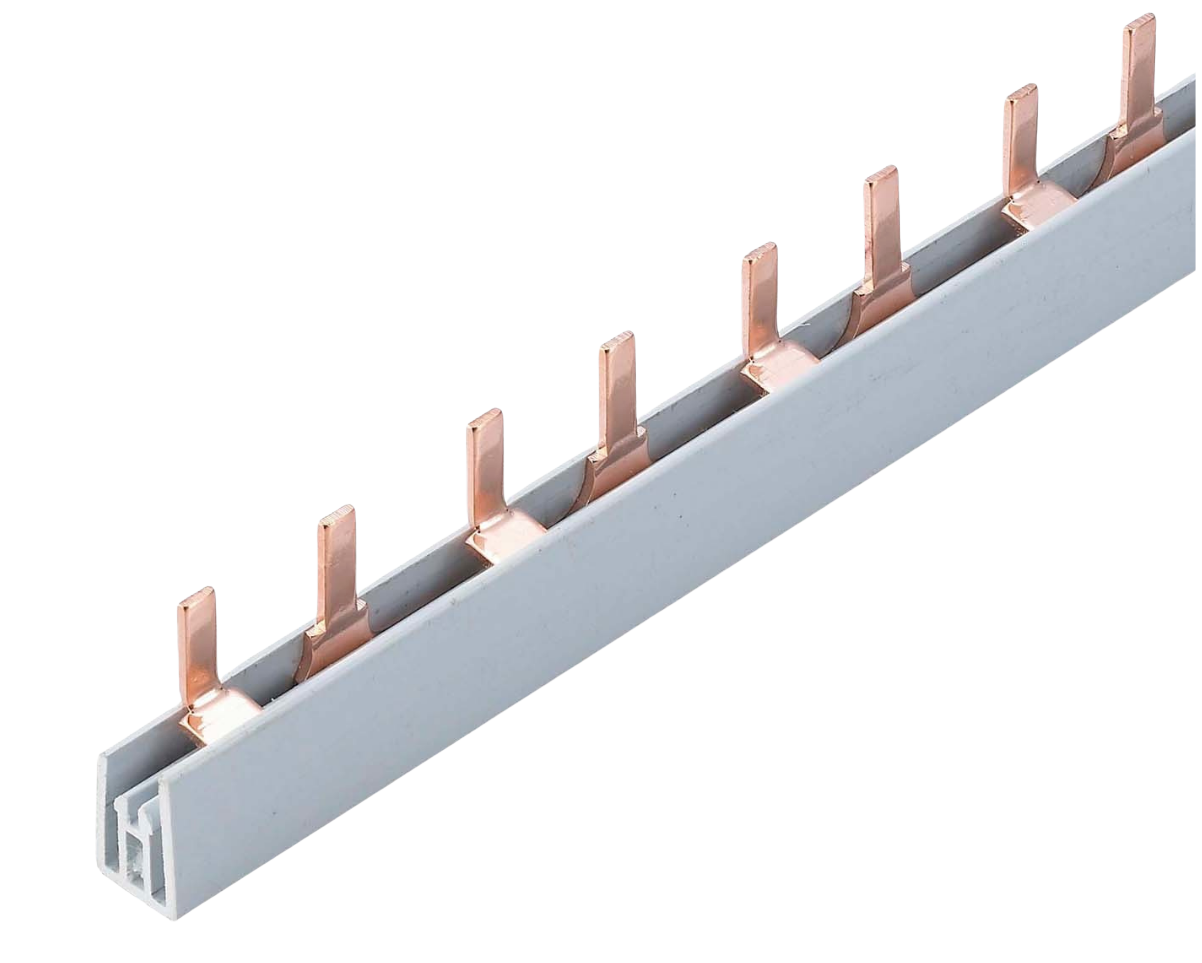

Essentially, a busbar is a metallic strip or bar that conducts electricity within a switchboard, distribution board, substation, battery bank (like in a solar setup), or other electrical apparatus. Its not some complicated, whiz-bang piece of technology; it's actually quite simple in its design. It's the role it plays that makes it so important. Think of it as the unsung hero, quietly keeping the electricity flowing where it needs to go.

Why use a busbar instead of just a bunch of wires? Well, imagine trying to connect multiple high-current wires together. It would be a messy, inefficient, and potentially dangerous situation! A busbar provides a clean, organized, and much safer way to manage and distribute large amounts of electrical current. It's all about efficiency and safety, two things you really want when dealing with electricity.

The key here is to visualize it. Picture a large, solid piece of metal connecting different circuits or components. That's your busbar. It allows for easy connection and disconnection of circuits, making maintenance and modifications much simpler. Now, let's dive into why they're so essential.

What Is A Electrical Bus Bar At Sue Alexander Blog

The Real Purpose

2. Understanding the Core Functionality of a Busbar

Alright, now that we know what a busbar is, let's talk about its purpose — and believe me, it's not just for show! The primary reason busbars exist is to distribute electrical power effectively and safely. They act as a common connection point for multiple circuits, allowing you to draw power from various sources and distribute it to numerous loads.

Think of a power plant. It generates a huge amount of electricity. That electricity needs to be distributed to homes, businesses, and industries. Busbars, within substations, play a crucial role in managing that flow. They're the traffic controllers of the electrical grid, ensuring that the right amount of power gets to the right place at the right time. Without them, chaos would ensue (think brownouts and blackouts galore!).

Furthermore, busbars provide a low-impedance path for electrical current. This is super important because lower impedance means less energy loss in the form of heat. Higher energy efficiency equals lower costs (and a happier planet!). They also help to minimize voltage drop, ensuring that the equipment connected to the system receives the appropriate voltage level. No one wants their appliances sputtering because the voltage is too low!

Beyond just distribution, busbars also offer a convenient way to connect and disconnect circuits. This makes troubleshooting and maintenance much easier. Need to isolate a section of the system for repairs? Just disconnect it at the busbar! It's a much safer and more efficient solution than trying to fumble around with a bunch of individual wires. It all boils down to safety, efficiency, and reliability.

Busbar Archives Brian Bell Trade Electrical

Busbars in Action

3. Exploring Common Applications of Busbars

So, where are these busbars hanging out, doing their thing? You might be surprised to learn they're practically everywhere! They're essential components in a wide range of electrical systems, from the small-scale to the very large.

One common place you'll find busbars is in electrical panels, both in residential and commercial buildings. These panels distribute power from the main service entrance to individual circuits within the building. The busbars within the panel provide a convenient and safe way to connect circuit breakers and distribute power to lights, outlets, and appliances. They're the backbone of your building's electrical system.

Another critical application is in substations. As mentioned earlier, substations are vital for managing the flow of electricity from power plants to consumers. Busbars in substations handle enormous amounts of current and play a crucial role in switching and protecting the electrical grid. They're the heavy lifters of the power distribution world.

You'll also find busbars in various industrial applications, such as in manufacturing plants, data centers, and transportation systems. Anywhere where large amounts of electrical power need to be distributed efficiently and reliably, you can bet there's a busbar involved. They're truly indispensable in modern electrical infrastructure. And even in smaller applications, like battery banks for solar systems, busbars help manage the DC current flow effectively. So, next time you see a solar panel installation, remember the busbar is working hard behind the scenes!

Electrical Busbar System Copper Bus Bars Manufacturer

Types of Busbars

4. Different Busbar Designs and Their Applications

Believe it or not, busbars aren't all created equal. They come in various shapes, sizes, and materials, each designed for specific applications and current-carrying capacities. Let's take a peek at some of the common types.

First up, we have rigid busbars. These are typically made from solid copper or aluminum bars and are used in high-current applications where mechanical strength and rigidity are important. Think of them as the "muscle cars" of the busbar world — powerful and robust.

Then there are flexible busbars, which are made from laminated copper or aluminum strips. These are more flexible and easier to install in tight spaces. They're like the "yoga instructors" of busbars, bending and flexing to fit where they're needed.

Another type is insulated busbars, which are coated with an insulating material to prevent accidental contact and short circuits. These are particularly useful in environments where safety is a top priority. They're the "safety-conscious" busbars, always looking out for potential hazards.

Finally, we have tubular busbars, which are hollow tubes made from copper or aluminum. These are often used in high-voltage applications due to their superior electrical and mechanical properties. They're like the "high-achievers" of the busbar family, excelling in demanding situations. The choice of busbar depends on factors such as current rating, voltage level, environmental conditions, and space constraints. Engineers carefully select the appropriate type to ensure optimal performance and safety.

What Is A Bus Bar In An Electrical Panel At Jefferson Patterson Blog

Ensuring Longevity

5. Maintenance and Best Practices for Busbar Systems

Like any electrical component, busbars require proper maintenance to ensure their long-term reliability and safety. Ignoring maintenance can lead to corrosion, overheating, and even catastrophic failures. Nobody wants that!

One of the most important maintenance tasks is regular inspection. Check for signs of corrosion, loose connections, and physical damage. Corrosion can increase resistance, leading to overheating and reduced performance. Loose connections can also cause arcing and potential fire hazards. Catching these issues early can prevent more serious problems down the road.

Another critical step is to ensure that all connections are clean and tight. Use a wire brush or other appropriate tool to remove any corrosion or debris from the contact surfaces. Then, tighten the connections to the recommended torque specifications. Properly tightened connections ensure good electrical contact and minimize resistance.

Finally, keep the busbar environment clean and dry. Dust, dirt, and moisture can contribute to corrosion and reduce the insulating properties of the busbar. Regularly clean the area around the busbar and take steps to prevent moisture from accumulating. With a little TLC, your busbars will keep humming along for years to come. Remember, a little maintenance goes a long way in ensuring the safety and reliability of your electrical system. Treat your busbars right, and they'll treat you right!

Understanding Busbar Function And Purpose EMS Industrial

FAQ

6. Your Burning Questions Answered

Still have some questions about busbars? No problem! Here are a few frequently asked questions to help clear things up:

7. Q

A: While theoretically possible, it's highly discouraged. Copper and aluminum are the preferred materials due to their excellent conductivity, corrosion resistance, and cost-effectiveness. Other metals may not be suitable for high-current applications and could pose safety risks.

8. Q

A: The size of the busbar depends on the amount of current it needs to carry. Consult an electrical engineer or qualified electrician to determine the appropriate size based on your specific application. Overloading a busbar can lead to overheating and potential fire hazards. It's always better to be safe than sorry!

9. Q

A: Like any electrical component, busbars can be dangerous if not handled properly. Always de-energize the system before working on or near busbars. Use appropriate personal protective equipment (PPE), such as insulated gloves and safety glasses. If you're not comfortable working with electricity, it's best to leave it to the professionals. Safety first!

10. Q

A: While both are conductive bars, they serve different purposes. A busbar distributes power (either phase/hot or DC), while a neutral bar provides a common return path for electrical current back to the source. They are typically connected differently within an electrical panel.